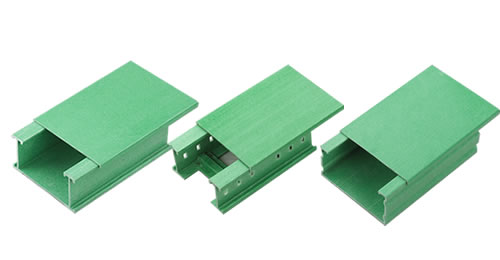

防火电缆桥架厂家喷涂技术要点

静电喷涂法一般是工件接地,喷枪带负高压电,粉末粒子在静电场的效果下飞向接地的待涂工件上,取得均匀的涂层,然后在固化炉中流平,形成均匀的薄膜,喷涂进程中剩余的粉末经过回收设备重复运用,它的特点是:①涂膜均匀程度较好,粉末损失较少;②在冷态下涂覆,一般一次喷涂可达到100μm左右。

The electrostatic spraying method generally involves grounding the workpiece, with the spray gun carrying negative high voltage electricity. The powder particles fly towards the grounded workpiece under the effect of the electrostatic field to obtain a uniform coating, which is then flattened in the curing furnace to form a uniform thin film. The remaining powder during the spraying process is reused by recycling equipment. Its characteristics are: ① good coating uniformity and less powder loss; ② When coated in a cold state, a single spray can generally reach around 100 μ m.

粉末涂装的粉末运用率高,从涂装整个进程比较,防火电缆桥架厂家施工所需费用省,经济效益高。

The powder application rate of powder coating is high. Compared with the entire coating process, the construction cost of fireproof cable tray manufacturers is saved, and the economic benefits are high.

粉末涂层较厚,具有较好的机械性能和化学性能,尤其与金属底材的附着力、耐冲击性、耐磨性和耐腐蚀性等都优于溶剂型涂料。

The powder coating is thicker and has better mechanical and chemical properties, especially in terms of adhesion, impact resistance, wear resistance, and corrosion resistance to metal substrates, which are superior to solvent based coatings.

由于一 次喷涂可得到厚度为40~80μm的涂层,因此一道粉末涂层能够代替几道溶剂型涂层,简化工序,防火电缆桥架厂家节约人力、物资消耗,缩短涂装周期,减少在制品积存。

Due to the ability to obtain a coating with a thickness of 40-80 μ m in one spray, a powder coating can replace several solvent based coatings, simplify the process, save manpower and material consumption for fire-resistant cable tray manufacturers, shorten the coating cycle, and reduce the accumulation of work in progress.

粉末静电喷涂是防火电缆桥架厂家将固体粉末直接堆积在工件外表,堆积率高。未堆积的粉末经过粉末回收设备重复运用,因此运用率高,一般可达85以上,而溶剂型涂料仅30~60。

Powder electrostatic spraying is a method used by fire-resistant cable tray manufacturers to directly deposit solid powder onto the surface of the workpiece, resulting in a high accumulation rate. The non stacked powder is reused through powder recycling equipment, resulting in a high utilization rate of generally over 85%, while solvent based coatings only have a utilization rate of 30-60%.

不含有机溶剂,涂装进程不产生溶剂蒸汽,无空气污染,不需要严格的环境保护措施,相应地不存在废气排放管理等困难。

Does not contain organic solvents, does not produce solvent vapors during the coating process, has no air pollution, does not require strict environmental protection measures, and correspondingly, there are no difficulties in waste gas emission management.

下一篇:电缆桥架的运输如何做好分配?

相关文章 / Recommended news

济南电缆桥架到底需不需要跨接

济南电缆桥架到底需不需要跨接 安装桥架

安装桥架 安装桥架

安装桥架 安装桥架

安装桥架 防火桥架

防火桥架