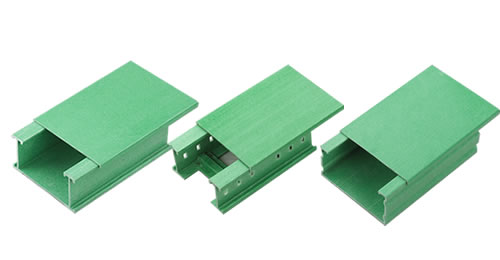

防火电缆桥架厂家的施工要注意什么?

当盖板掩盖时,线槽接口应与插槽盖接口移位,避免两个接口堆叠,从而能够提高整个线槽的刚性。

When the cover plate is concealed, the slot interface should be shifted from the slot cover interface to avoid stacking two interfaces, thereby improving the rigidity of the entire slot.

衔接衔接头时的施工办法。内部(外部)衔接头附件是在相同规格线之间运用封闭。当结构能够采用约15-20厘米的相同尺寸的截面,而不是衔接头部成品。“衔接器”一般嵌入线槽(内衔接器)的内部,以坚持整个线路槽的外观。将“关节”钻头更好,用自攻螺钉或芯铝钉固定“衔接器”。

Construction methods for connecting joints. Internal (external) connector attachments are enclosed between lines of the same specification. When the structure can adopt a cross-section of about 15-20 centimeters of the same size, instead of connecting the head finished product. The "connector" is generally embedded inside the cable tray (inner connector) to maintain the appearance of the entire cable tray. Better use a "joint" drill bit and secure the "connector" with self tapping screws or core aluminum nails.

缺少阳角关节时的施工办法。刚性角接头用于线槽作为90°曲折的线槽。在制作时,插槽侧高度尺寸高度尺寸,在一条线槽的结尾底部,而且用切开切出DIPK。在另一条线槽端,每次切开沿凹槽的底外表和两个槽的旁边面的刀,防火电缆桥架厂家切开深度是凹槽侧的高尺寸,然后切开曲折槽的底部,然后曲折部分衔接到前部槽口用铆钉固定。相应的槽盖曲折,而且能够发现线槽由90°曲折制成。

The construction method when there is a lack of male corner joints. Rigid corner joints are used for trunking as 90 ° winding trunking. During production, the height dimension of the slot side is at the bottom of the end of a wire slot, and DIPK is cut out by cutting. At the other end of the cable tray, each time a knife is cut along the bottom surface of the groove and the side surfaces of the two grooves, the fireproof cable tray manufacturer cuts to the height of the groove side, then cuts the bottom of the curved groove, and the curved part is connected to the front slot and fixed with rivets. The corresponding slot cover is tortuous, and it can be observed that the wire slot is made of a 90 ° twist.

电缆桥架时的施工办法。当线槽在90°内曲折时运用曲线角接头,这能够经过切开罐自身来到达目的。这种做法如下:防火电缆桥架厂家在线槽的双面槽侧,它在内弯的旁边面上穿插。运用铁切成两个45°的间隙,然后线槽减小到间隙,防火电缆桥架厂家使得凹槽的旁边面向外,然后铆接固定固定,以便制作简单,凹槽相应部分的盖能够曲折,而且能够在盖子的两边切开两边,而且能够制作槽盖。

Construction methods for cable trays. When the trunking bends within 90 degrees, use curved corner joints, which can be achieved by cutting open the can itself. This approach is as follows: The fire-resistant cable tray manufacturer inserts the double-sided groove side of the cable tray on the side of the inner bend. Cut the iron into two 45 degree gaps, then reduce the cable tray to the gap. The fire-resistant cable tray manufacturer makes the side of the groove face outward, and then rivet and fix it for easy production. The cover of the corresponding part of the groove can be bent, and both sides of the cover can be cut open, and the groove cover can be made.

下一篇:济南桥架的用途有哪些?

相关文章 / Recommended news

济南电缆桥架到底需不需要跨接

济南电缆桥架到底需不需要跨接 安装桥架

安装桥架 安装桥架

安装桥架 安装桥架

安装桥架 防火桥架

防火桥架