济南电缆桥架安装全流程注意事项解析

电缆桥架作为电力与通信线路的重要载体,其安装质量直接影响系统运行与使用寿命。从施工准备到验收交付,每个环节均需严格遵循技术规范,确保桥架系统稳固可靠。

As an important carrier of power and communication lines, the installation quality of cable trays directly affects the safety and service life of the system operation. From construction preparation to acceptance and delivery, every step must strictly follow technical specifications to ensure the stability and reliability of the bridge system.

安装前需对施工环境进行勘查。确认建筑结构承重能力,混凝土强度需达到C20以上方可进行膨胀螺栓固定。对于钢结构厂房,需检测横梁挠度,确保桥架荷载不超过设计值的70%。环境温湿度同样关键,低温环境下金属桥架收缩率可达0.02%/℃,需预留热胀冷缩补偿量;潮湿区域则需选用镀锌厚度≥65μm的桥架,防止锈蚀。

A comprehensive survey of the construction environment is required before installation. The key is to confirm the load-bearing capacity of the building structure, and the concrete strength must reach C20 or above before expansion bolt fixation can be carried out. For steel structure factories, it is necessary to detect the deflection of the crossbeam to ensure that the bridge load does not exceed 70% of the design value. The temperature and humidity of the environment are equally critical. The shrinkage rate of metal cable trays can reach 0.02%/℃ in low-temperature environments, and compensation for thermal expansion and contraction needs to be reserved; In damp areas, cable trays with a galvanized thickness of ≥ 65 μ m should be selected to prevent rusting.

工具与材料验收是质量控制的首道关卡。电动扳手扭矩需校准±5%,确保M10螺栓紧固力矩达标。桥架本体检测需涵盖外观、尺寸与镀层厚度,使用涂层测厚仪随机抽检,镀锌层厚度不足60μm或喷塑层附着力不达1级标准的产品禁止使用。跨接导线需采用4mm²铜编织带,截面积不足将影响接地连续性。

The acceptance of tools and materials is the first hurdle in quality control. The torque of the electric wrench needs to be calibrated to ± 5% to ensure that the tightening torque of the M10 bolt meets the standard. The inspection of the bridge body should cover appearance, size, and coating thickness. A coating thickness gauge should be used for random sampling. Products with a galvanized layer thickness of less than 60 μ m or a spray coating adhesion that does not meet Level 1 standards are prohibited from use. The jumper wire needs to use 4mm ² copper braided tape, and insufficient cross-sectional area will affect grounding continuity.

定位划线阶段需建立三维坐标系。水平误差每米不得超过2mm,全长偏差控制在10mm以内,使用激光投线仪配合墨斗弹线。转角处需采用45°拼接工艺,避免直角弯头造成的线路磨损。对于多层桥架,垂直间距需预留200mm以上,便于散热与维护,底部距地面高度不宜低于2.5米,防止机械损伤。

The positioning and marking stage requires the establishment of a three-dimensional coordinate system. The horizontal error shall not exceed 2mm per meter, and the overall deviation shall be controlled within 10mm. A laser projector shall be used in conjunction with an ink fountain to mark the line. 45 ° splicing technology should be used at the corner to avoid line wear caused by right angle bends. For multi-layer cable trays, a vertical spacing of at least 200mm should be reserved for heat dissipation and maintenance. The bottom should not be less than 2.5 meters above the ground to prevent mechanical damage.

支吊架安装是确保桥架稳定性的核心环节。膨胀螺栓埋深需达到80mm以上,使用扭矩扳手分两次紧固,达到设计值70%,二次复紧间隔24小时。吊架间距需根据桥架规格调整,200mm宽桥架间距不得超过1.5米,超过400mm宽需增设纵向抗震支吊架。对于非直线段,每3米需增设固定支架,防止变形。

The installation of supports and hangers is the core link to ensure the stability of the bridge. The burial depth of the expansion bolt should be at least 80mm, and it should be tightened twice with a torque wrench. The first tightening should reach 70% of the design value, and the second tightening should be spaced 24 hours apart. The spacing between hangers should be adjusted according to the specifications of the bridge frame. The spacing between 200mm wide bridge frames should not exceed 1.5 meters, and longitudinal seismic support hangers should be added if the width exceeds 400mm. For non-linear sections, fixed brackets should be added every 3 meters to prevent deformation.

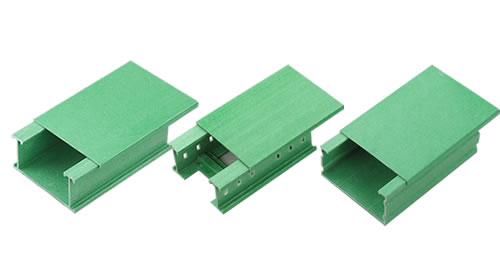

桥架组装需遵循“先下后上、先内后外”原则。连接板螺栓紧固顺序需对称交叉进行,避免单边受力导致密封不严。盖板安装前需清理内部杂物,使用吸尘器配合粘毛滚筒,防止金属碎屑损伤电缆绝缘层。对于防火桥架,需检查防火封堵是否严密,防火泥填充率需达95%以上,孔洞处需加装防火包。

The assembly of cable trays should follow the principle of "from bottom to top, from inside to outside". The tightening sequence of the connecting plate bolts should be symmetrically crossed to avoid insufficient sealing caused by unilateral force. Before installing the cover plate, it is necessary to clean the internal debris and use a vacuum cleaner in conjunction with a glue roller to prevent metal debris from damaging the cable insulation layer. For fireproof cable trays, it is necessary to check whether the fireproof sealing is tight, the fireproof mud filling rate should be above 95%, and fireproof bags should be installed at the holes.

接地处理是保障系统的关键步骤。每段桥架需保证2处以上接地连接,跨接导线与桥架接触面需去除镀层,露出金属本色后涂抹导电膏。总等电位联结箱接地电阻不得大于1Ω,使用接地电阻测试仪分三次测量取平均值。对于强电与弱电共架场景,需采用分隔板隔离,间距保持300mm以上,防止电磁干扰。

Grounding treatment is a crucial step in ensuring system safety. Each section of the bridge should ensure at least 2 grounding connections, and the contact surface between the jumper wire and the bridge should have its coating removed. After exposing the natural color of the metal, conductive paste should be applied. The grounding resistance of the total equipotential bonding box shall not exceed 1 Ω, and the grounding resistance tester shall be used to measure the average value in three separate measurements. For the scenario of strong and weak electricity sharing the same frame, a partition board should be used for isolation, with a spacing of at least 300mm to prevent electromagnetic interference.

特殊环境安装需采取专项措施。腐蚀性区域桥架需做三防处理,底漆干膜厚度≥50μm,面漆耐盐雾性能需达720小时以上。高温场所应选用耐温150℃以上的硅橡胶密封条,桥架顶部需加装隔热板。振动设备附近需安装弹性支架,固有频率避开设备振动频率50%以上,避免共振导致的疲劳损伤。

Special measures need to be taken for installation in special environments. Corrosive area cable trays need to undergo three protection treatments, with a dry film thickness of ≥ 50 μ m for the primer and a salt spray resistance of at least 720 hours for the topcoat. Silicone rubber sealing strips with a temperature resistance of 150 ℃ or above should be used in high-temperature places, and insulation boards should be installed on the top of the bridge. Elastic supports should be installed near vibration equipment, with natural frequencies avoiding over 50% of the equipment's vibration frequency to prevent fatigue damage caused by resonance.

验收阶段需进行多维度检测。外观检查采用5倍放大镜,查看焊缝、涂层缺陷。载荷试验需加载设计值的150%,持续2小时无变形。接地连续性测试需在潮湿环境下进行,确保接触电阻≤0.01Ω。提交的竣工资料需包含三维走向图、材料合格证及第三方检测报告,实现全生命周期可追溯。

Multi dimensional testing is required during the acceptance stage. The appearance inspection adopts a 5x magnifying glass, focusing on inspecting weld seams and coating defects. The load test needs to be loaded to 150% of the design value for 2 hours without permanent deformation. The grounding continuity test should be conducted in a humid environment to ensure that the contact resistance is ≤ 0.01 Ω. The submitted completion documents must include a three-dimensional directional diagram, material qualification certificate, and third-party inspection report to achieve full lifecycle traceability.

本文由济南电缆桥架友情奉献.更多有关的知识请点击 http://www.sdhangfeng.com 真诚的态度.为您提供为的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from Jinan Cable Bridge For more related knowledge, please click http://www.sdhangfeng.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.山东电缆桥架

下一篇:不锈钢电缆桥架散热计算解析:从理论到实践的科学指南

相关文章 / Recommended news

- 济南电缆桥架选购指南:热镀锌与热浸锌一字之差,应用场景与天壤之别

- 山东工程人必看!桥架安装验收7大硬标准,少一项都要返工,附详细数据

- 济南厂房福音!大跨距桥架破解3大痛点,加强筋加,安装省一半钱

- 山东工程人警惕!桥架敷线踩这坑必返工,监理当场叫停,国标早有明确规定

- 济南人避坑!桥架≠线槽,90%工程人都搞混,一字之差差千里

- 避坑指南!山东电缆桥架规格别瞎选,偏大浪费偏小隐患大,国标早就定好了

- 济南人必看!铝合金电缆桥架选对厚度,耐用又省心,90%的人选错踩坑

- 山东人必看!电缆桥架不是“铁架子”,藏着建筑用电的密码,90%的人都不懂

- 800kg/m抗压!济南电缆桥架,破解3大工程痛点,工期省30%

- 3种类型+98%散热!山东电缆桥架,选对不踩坑,布线效率翻倍

阳极氧化铝合金桥架

阳极氧化铝合金桥架 托盘式电缆桥架

托盘式电缆桥架 梯式电缆桥架

梯式电缆桥架 梯式不锈钢电缆桥架

梯式不锈钢电缆桥架 深灰色金属防火电缆桥架

深灰色金属防火电缆桥架